How to Hold Your Piece While Cutting

Resources:

http://its.foxvalleytech.com/MachShop3/basicmill/WorkHold.htm

https://cncminnesota.wordpress.com/2011/03/04/using-tabs-to-mill-a-flat-part/

http://el34world.com/Misc/Cnc/CNCTabs.htm

http://www.cnccookbook.com/CCCNCMillingWorkholding.html

Holding the Stock

One of the biggest issues when using a CNC to make a part is how do you hold the stock such that it doesn't get in the way of cutting the part.

There are only 3 ways to hold the part while cutting.

Below the Cut

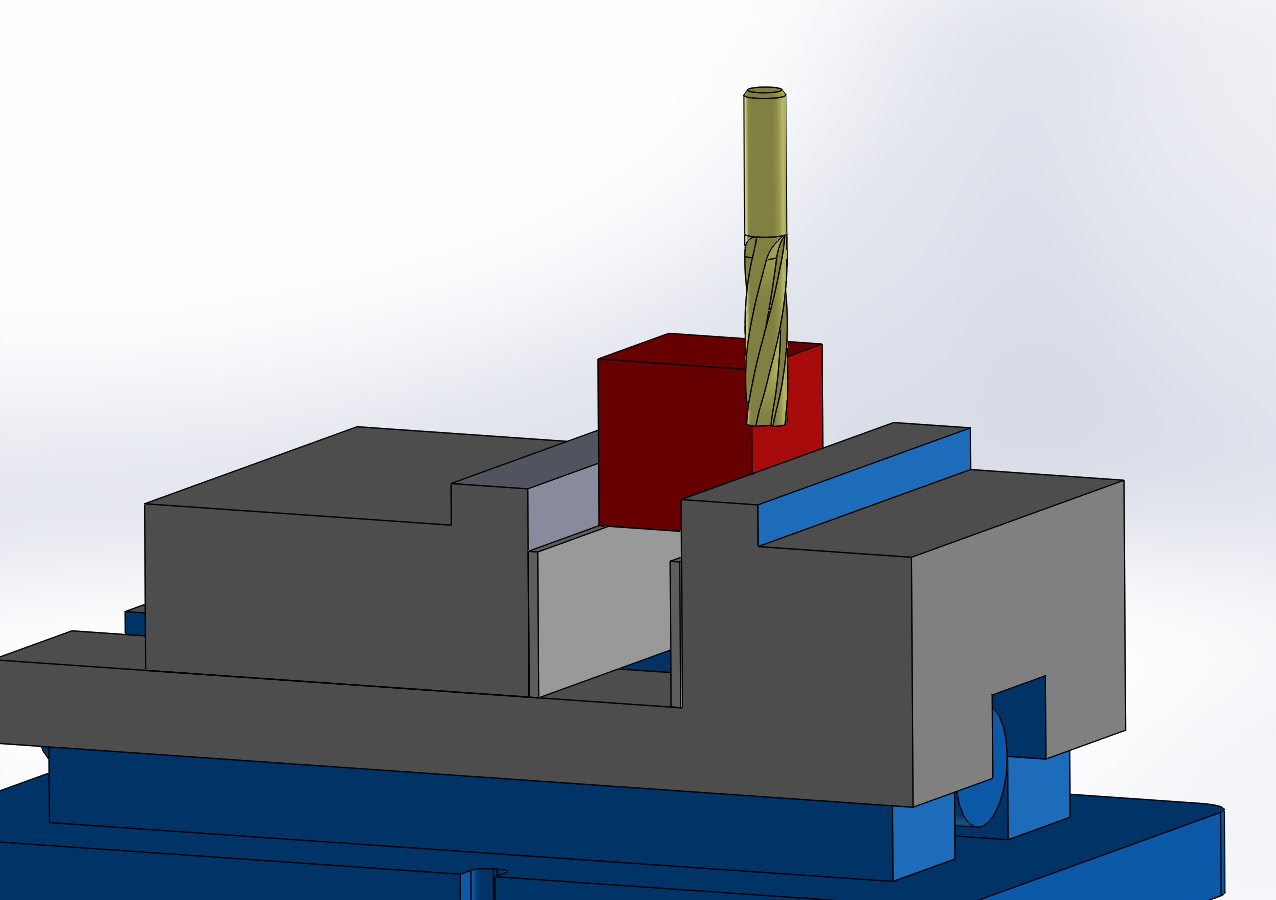

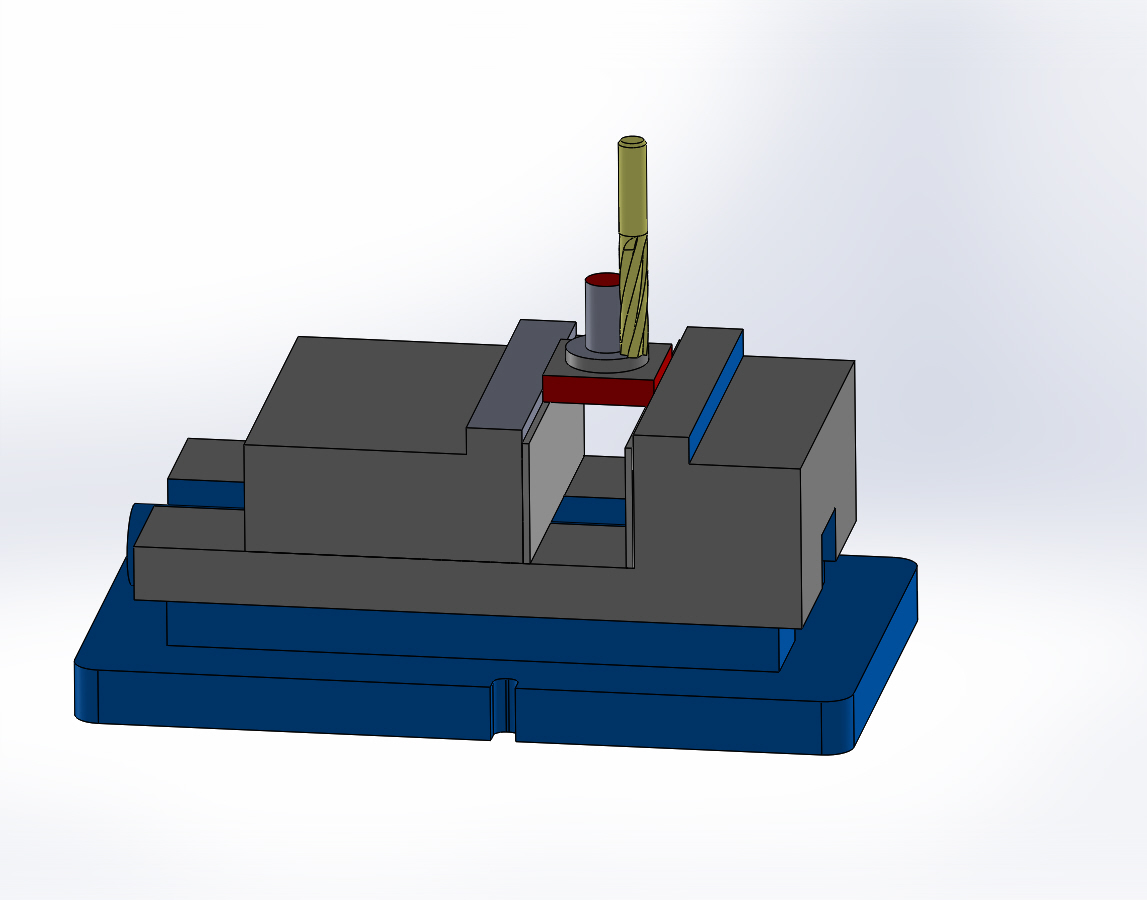

This is the most common way to hold the stock. For rectangular stock, you bring the stock to a height such that the tool can cut the outside of a part or inside, without hitting the vise. You should have at least ½ inch in the vise for gripping and the stock should extend above the vise no more than 3x what you have in the vise, and no more than 2x the thickness of the stock, jaw to jaw.

For a part with all faces milled, you can most times do the entire part above the jaws, leaving stock and then flip and finish.

Flip and then finish

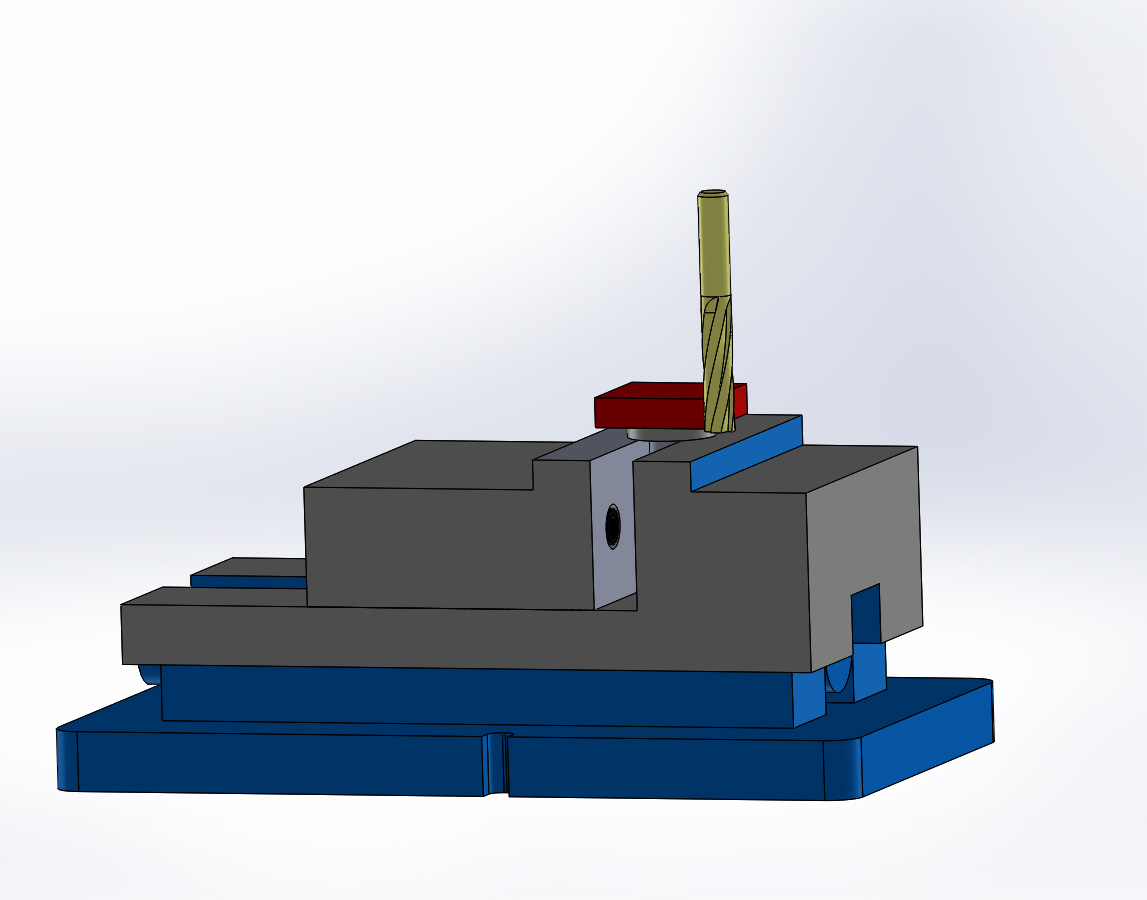

Outside the Cut

For interior cuts, you can simply hold the outside of the part and make interior cuts.

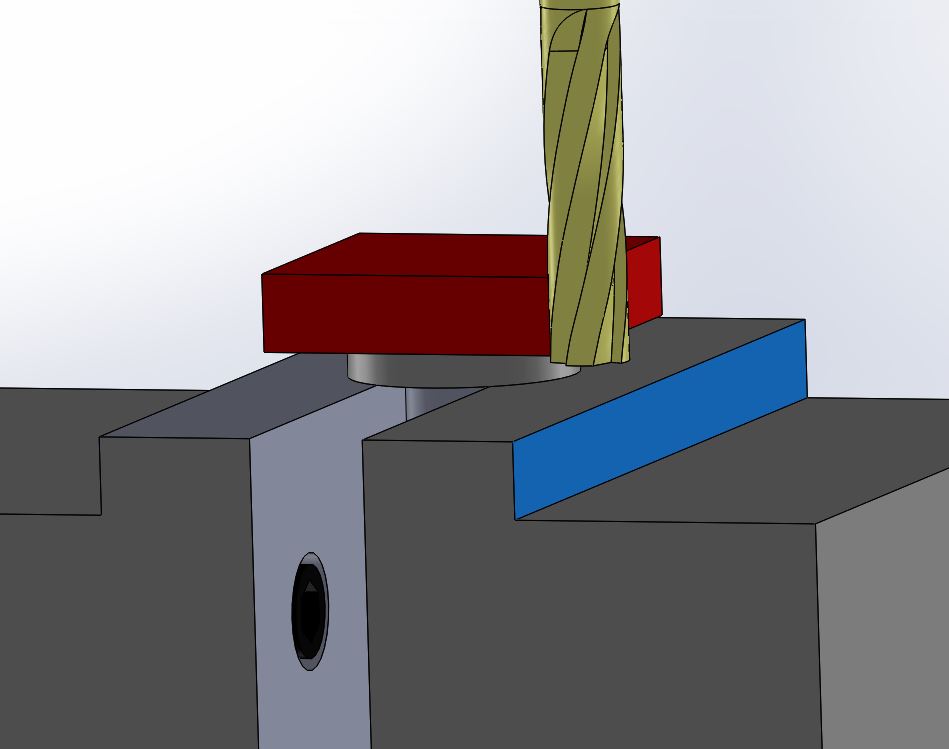

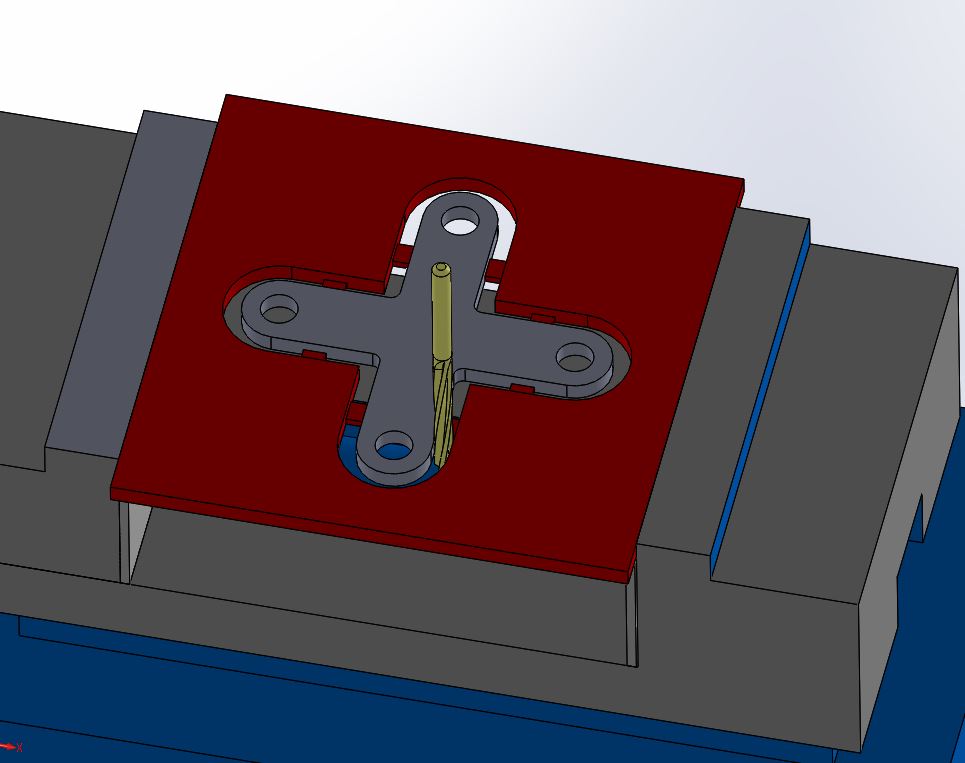

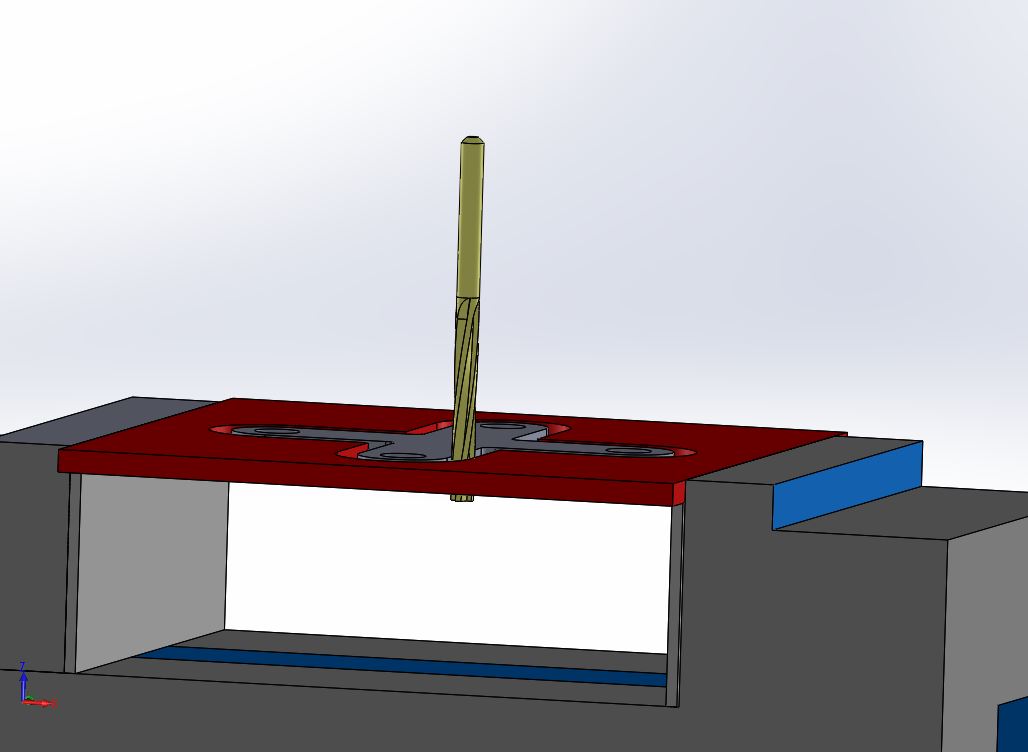

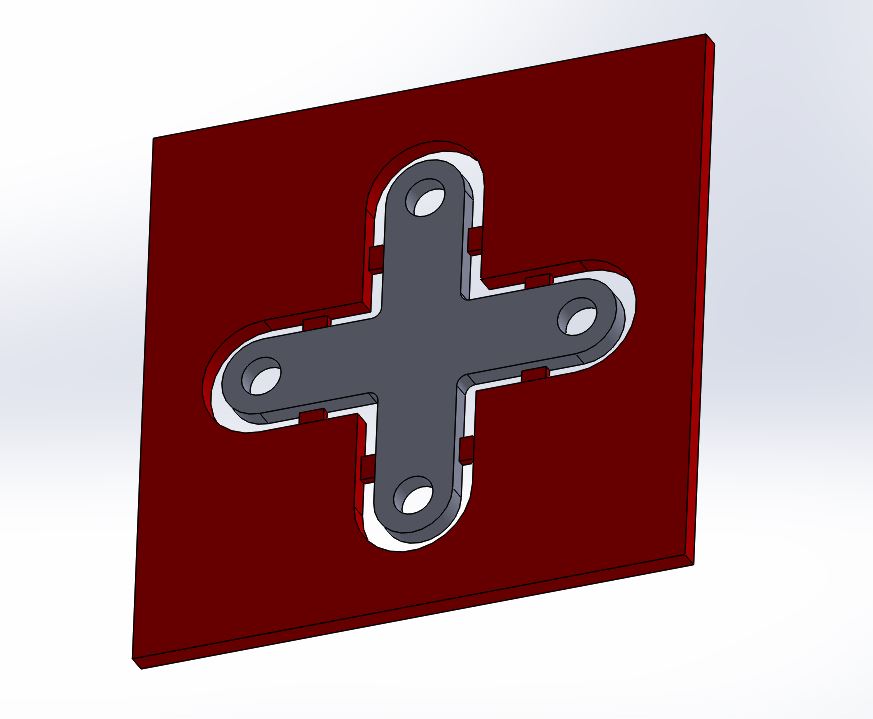

Tabs

A special case of this is tabs. To cut a profiled part out of plate stock, you can hold the exterior of the plate and in the interior of the plate cut the profile, but with tabs. Then a second manual operation is to cut the part from the stock and sand off the tab nubs. Tabs are usually not used with hand-coding due to complexity.

Like this: