Successfully Working Suede on a Laser Cutter

When I was finally cleared to operate the 150W laser cutter affectionately called “Bumblebee”, the first thing I did was to turn in a complete circle, eyeballing everything within walking distance as a potential target for a laser-drilled hole. After making an acrylic coaster and a few boxes, my focus shifted (no pun intended), and I started to think about making things I had a use for… the sorts of things that would not only look good, but would last a long time.

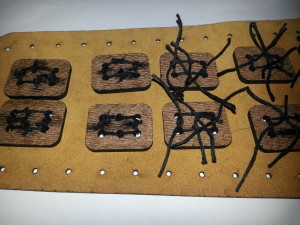

The first project I settled on was an archery bracer, made of buckskin suede. Rather than start with an existing pattern, this was created from scratch in Illustrator. For the 3/16th of an inch thickness of suede, a series of 1.5 mm holes in the pattern was enough allow the pattern parts to be laced together. 3/8″ holes were cut to place grommets in the suede, providing lacing positions. The pattern consisted of an outer wrap, intended to go all the way around the arm, and an inner piece which would sit flush against the forearm. Between them, a series of 10 “plates” of chipboard would provide armoring, absorbing the shock of impact in the event that the bowstring hit the bracer.

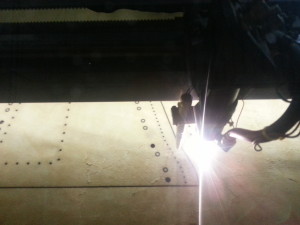

The armor bits were cut first from chipboard, and then the buckskin was placed into the cutter. Soft leather naturally has a wave pattern to it unless its been laid or pressed completely flat, so it’s important to smooth out as many wrinkles as possible prior to starting the cut. Immediately after the cut, the grommets were installed, and the armor bits were tied onto the doubler piece. The rolled edge was whip-stitched by hand and a braided leather cord was used as the lace for the doubler. Project complete!

**** IMPORTANT! When planning to work suede on a laser cutter, remember that the cut edge will be covered in soot from the burn of the laser and cut pieces should be handled as minimally as possible to keep soot from being tracked onto the worked piece. The best remedy for preparing pieces for handling is to cover the entire face of the piece in a layer of corn starch and use a toothbrush to smoothly and evenly brush the starch off of the suede face. The corn starch will carry the soot with it, leaving the edges of the pieces clean.

Leave a Reply

Want to join the discussion?Feel free to contribute!