BeagleBone hands-on workshop May 25th

What makes these tiny Linux computers great for hacker projects? The BeagleBoard.org project launched in 2008 and started a revolution in low-cost ARM computers (see Linaro.org). Beyond introducing the world to affordable low-power computers, the BeagleBoard has been the platform-of-choice for demonstrating open innovation on ARM—meaning—you can find real examples of people having tried to build something like what you have in mind, be it a remote drone quadcopter (100% compatible processor), open source handheld gaming system, object recognizing robot, mobile phone, video wall, connected home automation building blocks or remote underwater exploration vehicles.

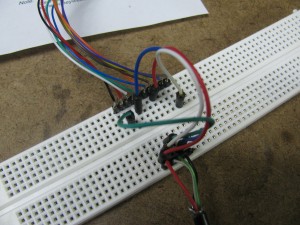

These computers are supported by most major Linux distributions (Ubuntu, Debian, Gentoo, Fedora, ArchLinux, etc.) and are capable of running Android, QNX, Windows Embedded and a number of other operating systems. The latest computer, the BeagleBone, provides a bit of an Arduino-like platform in that it enables access to an extensive amount of low-level I/O, including 7 analog inputs and over 60 general-purpose I/O pins multiplexed with an LCD interface, 2 I2C serial ports, 5 UART serial ports, an SPI port, a CAN bus, an secondary MMC/SD port, 6 pulse-width modulators and much more. At 720MHz and 256MB of RAM, with on-board Ethernet, microSD (for operating system storage), JTAG hardware debug, USB-to-serial and more, the BeagleBone is capable of running Python, Perl, Ruby, Java, JavaScript, GCC C++ compiler, autotools and a full GNOME desktop with word processors, spreadsheets, 3D games and web browsers.

I’m a co-founder of the project and I’ll be giving a hands-on workshop tonight at i3-Detroit, starting with the BeagleBone 101 presentation and diving into whatever topics attendees are looking to cover for their projects. I’ll leave a couple of boards in the space for people that want to hack on them and will be putting together some larger workshops at the space if there is enough interest. If you have a project you’d like to execute in the hackerspace using the BeagleBone, it’d be really great to work with you on it and help make i3-Detroit the home for advancement of low-power, high-performance embedded processing.