A better fuse block

As part of revamping i3’s front-door wiring, I needed to distribute several circuits of overcurrent-protected DC power. First, I grabbed an old bakelite fuse-block:

(Side note: Are you as sick as I am of trying to read the markings on a blown glass fuse? A little Sharpie solves that!)

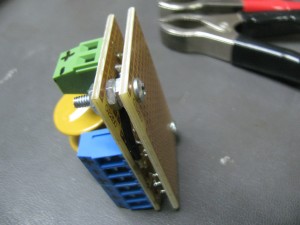

This left two unsolved problems, though: Gathering all the return leads, and replacing fuses if I shorted something while wiring. I decided to make a little power distribution block, instead:

The yellow discs are a 900mA Polyfuse and two 2.5A Polyfuses. The LEDs (and 1k resistors) don’t see voltage until the associated Polyfuse “trips”, so they indicate a faulted circuit. That allows me to commit stupidity while wiring things up, know about it, and not spend a glass fuse each time. It was also trivial to add extra screw terminals and a return bus, solving the other problem.

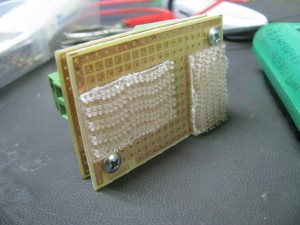

The next trick was mounting the thing without shorting out the traces on the bottom. It turned out to be easiest just to stand off a second piece of perfboard below it. These boards are so cheap ($0.39 ea?) it wasn’t worthwhile to make a dummy panel out of some other material.

Then a little Dual-Lock for mounting, and it’s done…

Just an added caution. The scheme here works great for low voltages and moderate currents, but for other uses be careful. Polyfuses can have a relatively low maximum voltage, and because the thermal mass is higher than the small wire in a glass fuse they can take a lot longer before tripping. But for this use, they rock!

Good point, Bob! Yes, the whole mess is running at 12V, and there are regular fuses upstream in the battery bank. This is designed so the polyfuses trip first in case of minor mishaps, but if something catastrophic happens to the supply wiring, the regular fuses should catch it.

As for moderate currents: Since the whole box is getting wired with 22AWG, I went one gauge smaller and grabbed some 24AWG for testing. Dead-shorted the fuse block with it. On the 2.5A position, I saw a peak of 18A for just an instant before the polyfuse tripped, and the wire got noticeably hot during that instant. On the 900mA position, it peaked around 8A with no detectable heat in the wire.

I didn’t jot down the “holding current” that the polyfuse lets through to keep itself heated and tripped, but it’s pretty low, certainly not a danger. Something to be aware of, though, for sure! Think of them as PTC resistors, rather than fuses.

One thing I learned while working as an EE at one of the big three is that the fuse is there to protect the wire, not the load. Yes, NOT the load. The fuse has to survive the load, but more importantly the wire must survive the fuse. So the fuse’s time*current rating must be well below the time*current rated fusing of the wire to be protected. For help there are standardized charts of copper wire fusing currents and safe operating currents. Such an “ampacity” table is at http://www.powerstream.com/Wire_Size.htm which shows 24AWG in a cable should be limited to 0.577A. At http://en.wikipedia.org/wiki/American_wire_gauge the table shows 24AWG copper wire will melt (fuse) at 29A or so. Somewhere between those numbers the insulation will surely give up its magic smoke, and that’s the real current limit the fuse must be well below.